有些情况下,我们需要在命令行下刷写 Leonardo 的 Firmware,一般的方法会遇到问题,原因是 Leonardo 进入 Bootloader 的方式比较特别:使用 1200波特率打开串口,Leonardo立即开始重启,重启之后运行的Booloader会让串口变化成为另外的编号,在这个过程中如果有握手,那么就开始 Firmware 的更新。因为中间串口会发生变化,因此一般的刷新方法都会都会碰到问题。

最近,我在网上网上看到了一个高手编写的代码,能够在 Windows下实现全自动的命令行刷写https://github.com/p1ne/arduino-leonardo-uploader/tree/master/windows

核心是一个 BAT 批处理文件,首先用 WMI 在系统中查找包含 Leonardo 字样的串口,然后用 mode 来设置这个串口,这样 Leonardo 就会去Reset。接下来再使用 WMI 在系统中查找Leonardo Bootloader 的字样确定新出现的串口号。然后就用 avrdude 来进行正常刷写了。

具体代码如下,相信看懂并不困难:

rem @echo off

setlocal

for /f "tokens=1* delims==" %%I in ('wmic path win32_pnpentity get caption /format:list ^| find "Arduino"') do (

call :resetCOM "%%~J"

)

:continue

:: wmic /format:list strips trailing spaces (at least for path win32_pnpentity)

for /f "tokens=1* delims==" %%I in ('wmic path win32_pnpentity get caption /format:list ^| find "Arduino Leonardo bootloader"') do (

call :setCOM "%%~J"

)

:: end main batch

goto :EOF

:resetCOM <WMIC_output_line>

:: sets _COM#=line

setlocal

set "str=%~1"

set "num=%str:*(COM=%"

set "num=%num:)=%"

set port=COM%num%

echo %port%

mode %port%: BAUD=1200 parity=N data=8 stop=1

timeout /t 1

goto :continue

:setCOM <WMIC_output_line>

:: sets _COM#=line

setlocal

set "str=%~1"

set "num=%str:*(COM=%"

set "num=%num:)=%"

set port=COM%num%

echo %port%

goto :flash

:flash

avrdude -v -CD:\arduino-1.8.4\hardware\tools\avr\etc\avrdude.conf -patmega32u4 -cavr109 -P%port% -b57600 -D -V -Uflash:w:./blink.ino.hex:i

特别注意的是:

1. 如果你在 Win10 上使用并且没有安装 Leonardo 驱动的话,设备名称不会出来 Arduino 字样,安装2个驱动(一个是 Bootloader的,一个是 Arduino 本身的)之后即可正常工作;

2. 注意最后 avrdude.conf 的路径不要搞错了

3. 要刷写的文件也是在最后一条命令上,我这里使用的是blink.ino.hex:i

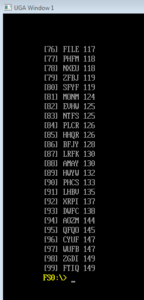

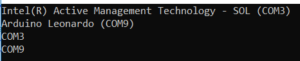

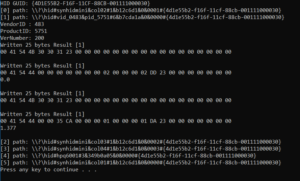

我这边实验的结果如下:

完整的log 如下:

D:\arduino-1.8.4\hardware\tools\avr\bin>f

D:\arduino-1.8.4\hardware\tools\avr\bin>rem @echo off

D:\arduino-1.8.4\hardware\tools\avr\bin>setlocal

D:\arduino-1.8.4\hardware\tools\avr\bin>for /F “tokens=1* delims==” %I in (‘wmic path win32_pnpentity get caption /format:list | find “Arduino”‘) do (call :resetCOM “%~J” )

” ) rduino-1.8.4\hardware\tools\avr\bin>(call :resetCOM “Arduino Leonardo (COM9)

D:\arduino-1.8.4\hardware\tools\avr\bin>setlocal

D:\arduino-1.8.4\hardware\tools\avr\bin>set “str=Arduino Leonardo (COM9)”

D:\arduino-1.8.4\hardware\tools\avr\bin>set “num=9)”

D:\arduino-1.8.4\hardware\tools\avr\bin>set “num=9”

D:\arduino-1.8.4\hardware\tools\avr\bin>set port=COM9

D:\arduino-1.8.4\hardware\tools\avr\bin>echo COM9

COM9

D:\arduino-1.8.4\hardware\tools\avr\bin>mode COM9: BAUD=1200 parity=N data=8 stop=1

Status for device COM9:

———————–

Baud: 1200

Parity: None

Data Bits: 8

Stop Bits: 1

Timeout: OFF

XON/XOFF: OFF

CTS handshaking: OFF

DSR handshaking: OFF

DSR sensitivity: OFF

DTR circuit: OFF

RTS circuit: ON

D:\arduino-1.8.4\hardware\tools\avr\bin>timeout /t 1

Waiting for 0 seconds, press a key to continue …

D:\arduino-1.8.4\hardware\tools\avr\bin>goto :continue

D:\arduino-1.8.4\hardware\tools\avr\bin>for /F “tokens=1* delims==” %I in (‘wmic path win32_pnpentity get caption /format:list | find “Arduino Leonardo bootloader”‘) do (call :setCOM “%~J” )

” ) rduino-1.8.4\hardware\tools\avr\bin>(call :setCOM “Arduino Leonardo bootloader (COM7)

D:\arduino-1.8.4\hardware\tools\avr\bin>setlocal

D:\arduino-1.8.4\hardware\tools\avr\bin>set “str=Arduino Leonardo bootloader (COM7)”

D:\arduino-1.8.4\hardware\tools\avr\bin>set “num=7)”

D:\arduino-1.8.4\hardware\tools\avr\bin>set “num=7”

D:\arduino-1.8.4\hardware\tools\avr\bin>set port=COM7

D:\arduino-1.8.4\hardware\tools\avr\bin>echo COM7

COM7

D:\arduino-1.8.4\hardware\tools\avr\bin>goto :flash

D:\arduino-1.8.4\hardware\tools\avr\bin>avrdude -v -CD:\arduino-1.8.4\hardware\tools\avr\etc\avrdude.conf -patmega32u4 -cavr109 -PCOM7 -b57600 -D -V -Uflash:w:./blink.ino.hex:i

avrdude: Version 6.3, compiled on Jan 17 2017 at 12:00:53

Copyright (c) 2000-2005 Brian Dean, http://www.bdmicro.com/

Copyright (c) 2007-2014 Joerg Wunsch

System wide configuration file is “D:\arduino-1.8.4\hardware\tools\avr\etc\avrdude.conf”

Using Port : COM7

Using Programmer : avr109

Overriding Baud Rate : 57600

AVR Part : ATmega32U4

Chip Erase delay : 9000 us

PAGEL : PD7

BS2 : PA0

RESET disposition : dedicated

RETRY pulse : SCK

serial program mode : yes

parallel program mode : yes

Timeout : 200

StabDelay : 100

CmdexeDelay : 25

SyncLoops : 32

ByteDelay : 0

PollIndex : 3

PollValue : 0x53

Memory Detail :

Block Poll Page Polled

Memory Type Mode Delay Size Indx Paged Size Size #Pages MinW MaxW ReadBack

———– —- —– —– —- —— —— —- —— —– —– ———

eeprom 65 20 4 0 no 1024 4 0 9000 9000 0x00 0x00

flash 65 6 128 0 yes 32768 128 256 4500 4500 0x00 0x00

lfuse 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00

hfuse 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00

efuse 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00

lock 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00

calibration 0 0 0 0 no 1 0 0 0 0 0x00 0x00

signature 0 0 0 0 no 3 0 0 0 0 0x00 0x00

Programmer Type : butterfly

Description : Atmel AppNote AVR109 Boot Loader

Connecting to programmer: .

Found programmer: Id = “CATERIN”; type = S

Software Version = 1.0; No Hardware Version given.

Programmer supports auto addr increment.

Programmer supports buffered memory access with buffersize=128 bytes.

Programmer supports the following devices:

Device code: 0x44

avrdude: devcode selected: 0x44

avrdude: AVR device initialized and ready to accept instructions

Reading | ################################################## | 100% 0.01s

avrdude: Device signature = 0x1e9587 (probably m32u4)

avrdude: safemode: hfuse reads as D8

avrdude: safemode: efuse reads as CB

avrdude: reading input file “./blink.ino.hex”

avrdude: writing flash (4142 bytes):

Writing | ################################################## | 100% 0.68s

avrdude: 4142 bytes of flash written

avrdude: safemode: hfuse reads as D8

avrdude: safemode: efuse reads as CB

avrdude: safemode: Fuses OK (E:CB, H:D8, L:FF)

avrdude done. Thank you.

D:\arduino-1.8.4\hardware\tools\avr\bin>goto :EOF

D:\arduino-1.8.4\hardware\tools\avr\bin>for /F “tokens=1* delims==” %I in (‘wmic path win32_pnpentity get caption /format:list | find “Arduino Leonardo bootloader”‘) do (call :setCOM “%~J” )

” ) rduino-1.8.4\hardware\tools\avr\bin>(call :setCOM “Arduino Leonardo bootloader (COM7)

D:\arduino-1.8.4\hardware\tools\avr\bin>setlocal

D:\arduino-1.8.4\hardware\tools\avr\bin>set “str=Arduino Leonardo bootloader (COM7)”

D:\arduino-1.8.4\hardware\tools\avr\bin>set “num=7)”

D:\arduino-1.8.4\hardware\tools\avr\bin>set “num=7”

D:\arduino-1.8.4\hardware\tools\avr\bin>set port=COM7

D:\arduino-1.8.4\hardware\tools\avr\bin>echo COM7

COM7

D:\arduino-1.8.4\hardware\tools\avr\bin>goto :flash

D:\arduino-1.8.4\hardware\tools\avr\bin>avrdude -v -CD:\arduino-1.8.4\hardware\tools\avr\etc\avrdude.conf -patmega32u4 -cavr109 -PCOM7 -b57600 -D -V -Uflash:w:./blink.ino.hex:i

avrdude: Version 6.3, compiled on Jan 17 2017 at 12:00:53

Copyright (c) 2000-2005 Brian Dean, http://www.bdmicro.com/

Copyright (c) 2007-2014 Joerg Wunsch

System wide configuration file is “D:\arduino-1.8.4\hardware\tools\avr\etc\avrdude.conf”

Using Port : COM7

Using Programmer : avr109

Overriding Baud Rate : 57600

avrdude: ser_open(): can’t open device “\\.\COM7”: The system cannot find the file specified.

avrdude done. Thank you.

D:\arduino-1.8.4\hardware\tools\avr\bin>goto :EOF